Nanotechnology based HDPE /PP bags for food grain storage

HDPE / PP Bags

Stage of adaption :

Post Harvest Stage

TECHNOLOGY BRIEF

As of now lot of food grains get damaged and infected annually due to poor and inadequate storage facilities, improper treatment, packing etc. Several developing countries, including India, suffer lack of proper and scientific storage facilities for food grains and sources. Hence, other costly and unsafe methods like insecticide sprays and labour-intensive methods are used. Individually and in combination with insecticide treated bags and direct sprays of insecticides on grains, were tried, but all achieved limited success. Thus, the newly designed ‘Bhapra bags’ possess novel treatment technology, in which the pesticide as a sandwich layer for increased efficacy, reusability and user-friendly approach by eliminating the contact with neither the grains nor the people managing them.

Since, no such similar technology/treatment exists/adopted and used in India, then it possesses great potential to capture the market very soon. We can anticipate a vast requirement for these handbags in the agriculture sector to minimize the loss of POST HARVEST products and in turn safeguard the economic governance of the country. The proposed technology would reduce the economic burden as well as it enhances the quality assurance.

BENEFITS

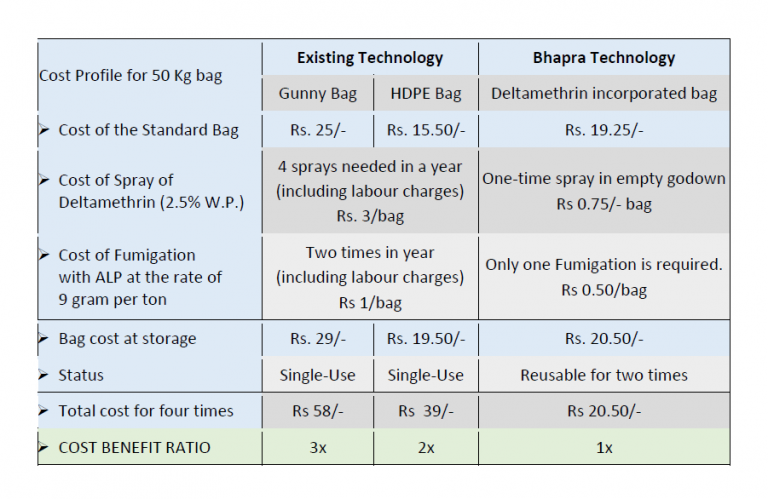

The new technology will not only prevent external infestations, but also prevent/contain internal infestations (to the minimum) of grain storage. The internal infestations, if at all there, would be contained in the bag itself (50kg) without advancing to the entire stack of bags even if in touch with each other. The innovation will be extremely cheap, cost efficient, easy to handle and of course highly safe, eco-friendly, and straight away, eliminating occupational hazards in handling bags in the current practice and prior arts.

TECHNOLOGY READINESS

Deployed in Largescale

Keeping in view that the newly Developed ‘Bhapra storage bags’ protect farmers’ harvest by reducing insect pest infestation on their postharvest storage, the Ministry of Consumer Affairs, Food and Public Distribution, Krishi Bhawan, New Delhi, has given approval and instructed Indian Grain Storage Management and Research Institute IGMRI (Hapur), to conduct the actual field trials (bio-efficacy and persistence activities during and over 15 months) at FCI godowns/warehouses. As per the requirement, we have initiated bulk production and supplied Bhapra storage bags (i.e., 9,240 treated bags + 5% extra bags (in each category of 50 Kg capacity) to the IGMRI for performing experiments to observe the condition of stored grains by periodic physical observations and testing of active residue for three different Geological locations in India. Soon after, we are planning to commercialize this product shortly after successful completion of actual field experiments at godowns/warehouses tests.

INTELLECTUAL PROPERTY

Technology Not Protected

CERTIFICATION

We are honoured to be picked out by the ‘Social Innovation Programme for Products’ (SPARSH-BIRAC), a Govt of India Enterprise undertaking, as an associate with our Plastic Bag Storage and eco-friendly BAG Project entitled, Development of novel, reusable insect pest protection woven/non-woven and knitted plastic HDPE/PP bags for food grain storage and Transportation/shipping. Since the project is in extreme public interest so is not simply being monitored, but fully funded as well by the SPARSH-BIRAC.

TARGET CUSTOMERS

SCALABILITY

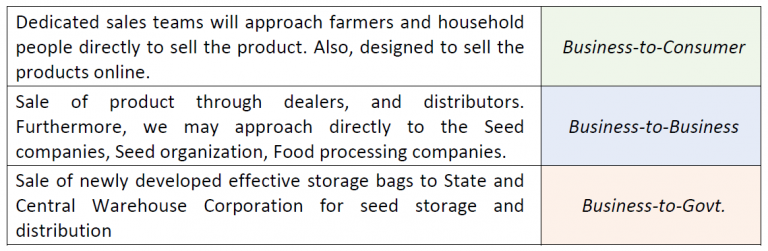

The global high-density polyethylene (HDPE) market reached a value of US$ 63 Billion in 2017. The market value is further planned to reach US$ 82 Billion by 2023, exhibiting a CAGR of about 4% during 2018-2023. If our product also enters the market the projected value may enhance to US$ 100 Billion by next three years. We will adopt Business-to-Business, Business-to-Consumer models (and Business-to-Government). Initially, we have concentrated on Business-to-State & the Central Warehousing Corporation.

LIMITATIONS

• Our superior quality grain storage bags should not cut open because they are reusable, thus one should carefully remove the Two rows of chain stitches placed on 25 mm folding.

• Bags which are not fit for recycling, should be sunburned in an appropriate high-temperature incinerator with effluent scrubbing or to be thrown away as per existing guidelines as prescribed by the Central Insecticides Board.

• We have offered an alternative eco-friendly disposal method such as, these bags can be used for nursery and/or road making by mixing with tar. Furthermore, we are offering a new bag with free of cost in return of 10 used bags.

TECHNOLOGY COST

SOCIAL IMPACT

According to the Agricultural Ministry, India is expected to produce 277.49 million tonnes of food grains in 2017 -2018. In which, 109.7, 97.11, 45.42 and 23.95 million tons of rice, wheat, coarse grains, and pulses, respectively. Despite of the surplus production of the food grains, we lose a huge proportion due to lack of good storage facilities, which contribute to pest infestations. Post-harvest loss of grains 10-25 % due to pests. Based on the analytical and biological properties of our products, we have identified that the deltamethrin incorporated as a thin layer between two protective PP/HPDE sheets would be an ideal for long storage of stored grains, without any pest infestation. To commercialize the product the actual field evaluations are undergoing from the Indian Grain Storage Management and Research Institute (IGMRI, Hapur). They will perform the bio-efficacy and persistence activities at FCI godowns/warehouses during and over 15 months to observe the condition of stored grain for three different Geological locations of India. The road map has already been set up to conduct numerous tests to commercialize the product. Since, no such similar technology/ treatment exists/adopted and practiced in India, so it has great potential to capture the market very soon. We can anticipate a vast need for these bags in the agriculture sector to minimize the loss of agricultural produce and in turn safeguard the economic system of the country.

CONTACT

kisanmitr@indiancst.in

TOLL FREE

1800 258 2010

ONLINE HELP DESK

+91 97 429 79 111